- My Portal

- Search

- Advise & Solutions

- Industries

- Calendar

- Solicitations

- Research

- tab 9

- tab 10

- tab 11

- tab 12

- tab 13

- tab 14

- tab 15

- tab 16

- tab 17

- tab 18

- tab 19

- tab 20

Catalog & Support

-

Instrumentation & Services

Find Products, Service Centers, Dealerships, Manuals, and more.

-

Business Services

Companies & Community

Support

Resources

____ This section requires a Corporate membership ____

Products & Services Wanted

- Article

- Publisher

- Contact

- tab 8

- tab 9

- tab 10

- tab 11

- tab 12

- tab 13

- tab 14

- tab 15

- tab 16

- tab 17

- tab 18

- tab 19

- tab 20

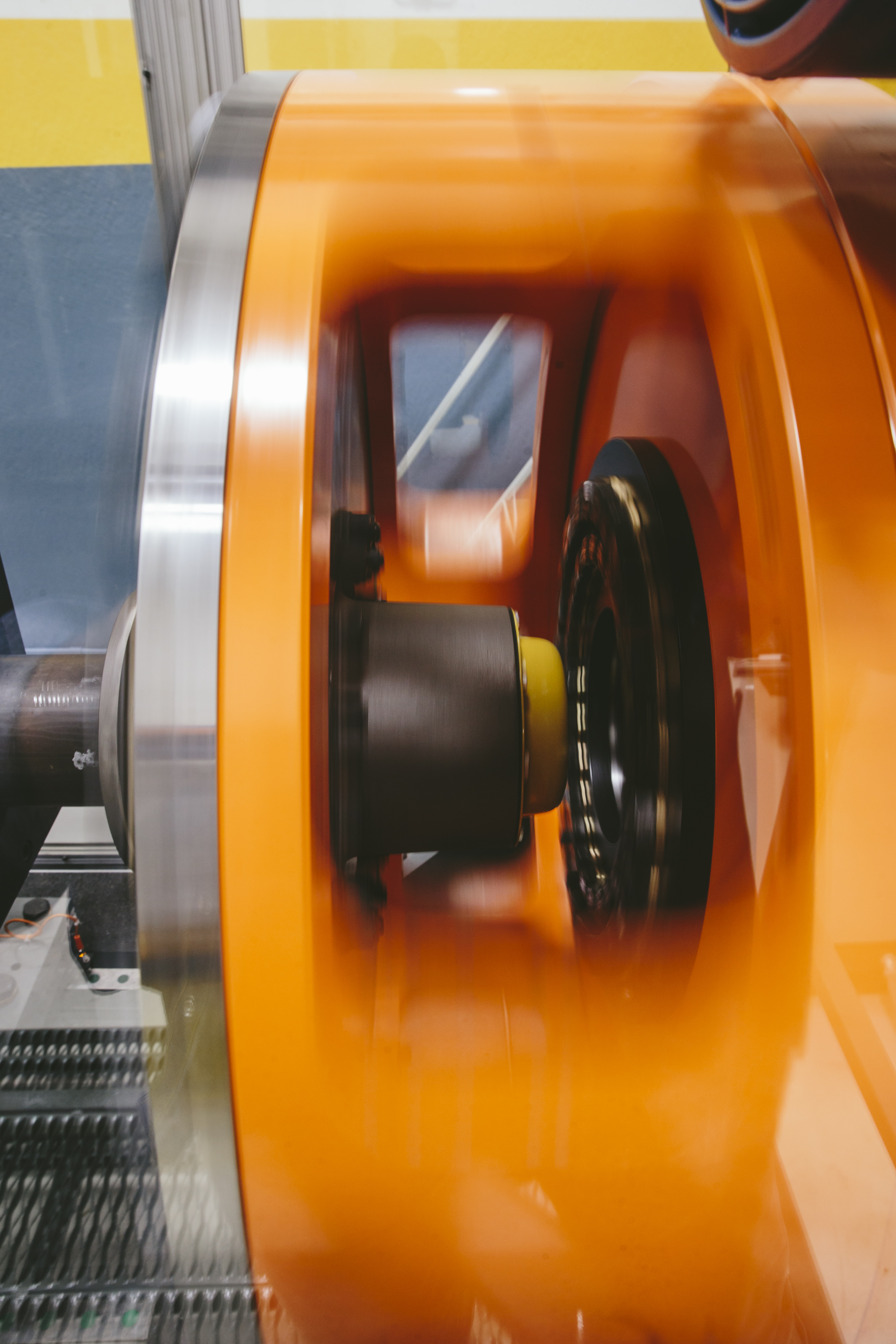

GKN Wheels & Structures held an open day on 24 May 2017 at its site in Woodridge, Illinois, where visitors saw demonstrations of the company's extensive wheel and hub testing capabilities, including a new, state-of-the-art, hub test stand. Reflecting GKN's market leadership in the design, development and manufacture of off-highway wheels and hubs, the new hub testing equipment has been commissioned to complement the company's existing wheel testing equipment, providing a dedicated and comprehensive wheel and hub test facility for customers across North America and further afield. Aaron Dahl, GKN's Chief Engineer, America, commented: Visitors to the site were given demonstrations of each of the test machines in operation, including cornering and radial fatigue wheel testing equipment. This included cornering tests of both agricultural implement and construction wheels, showcasing the company's unique ability to carry out bolted joint analysis as well as other strain gauge simulation testing. Drum tests were also running throughout the day on both agricultural and construction wheels. The new hub test stand was operating with the company's largest capacity hub, demonstrating dynamic cornering fatigue testing of the hub and spindle assembly. With GKN controlling the test load, spindle length, and test speed to replicate the maximum bearing loads of the system under the most extreme conditions, high-capacity agricultural and construction hubs can now be tested at the Woodridge facility, virtually eliminating the need for expensive and time-consuming field testing. By undertaking testing in this real-world environment, wheel-testing can now be carried out to simulate virtually any operating conditions, providing accurate performance data which is not only invaluable to customers, but also informs the company's manufacturing, development and investment plans. The ability to apply loads up to 100,000 lbs, makes this the largest known hub testing machine in the world, enabling GKN's engineers to develop larger hubs more quickly and more efficiently to meet the needs of the customer. Paul Wyatt, GKN Wheels & Structures Managing Director, concluded: We were delighted to welcome visitors to our open day, where they received a full, in-depth tour of the complete site, as well as having the opportunity to meet and discuss their individual requirements with both our leadership team and our highly-skilled engineers. We are incredibly proud of this facility which, following significant investment from the GKN group, has been completely re-modelled to incorporate the hub test equipment. Woodridge is an established centre of excellence for our wheel business and a real showcase for our engineering experience and expertise. We now look forward to continuing to set new standard for wheels and hub systems worldwide.

All Registered Trademarks, brand names and logos are respected and their ownership acknowledged. They are used on this website for information and reference purposes only. Test Interest doesn't assume any other implication or representation.